Table of Content

▲- 1. Introduction

- 2. What is 3D Printing?

- 3. How 3D Printing Works in Construction

- Table: 3D Printing Process in Construction

- 4. Benefits of 3D Printing in Real Estate Construction

- 5. Applications of 3D Printing in Construction

- 6. Case Studies of 3D Printing in Real Estate

- 7. Challenges and Limitations of 3D Printing in Construction

- 8. Future Trends of 3D Printing in Real Estate

- Conclusion

3D printing, a technology once reserved for prototyping and manufacturing, is revolutionizing various industries, including construction. The real estate construction sector is witnessing significant changes due to 3D printing, leading to faster, cheaper, and more sustainable building processes. This article explores the impact of 3D printing on real estate construction, its benefits, challenges, and future prospects.

1. Introduction

The construction industry has been slow to adopt new technologies compared to other sectors. However, the introduction of 3D printing is changing that narrative. By enabling the rapid construction of buildings with reduced labor costs and materials waste, 3D printing is transforming how we think about real estate development. This article will delve into how this innovative technology is disrupting the construction industry and what it means for the future of real estate.

2. What is 3D Printing?

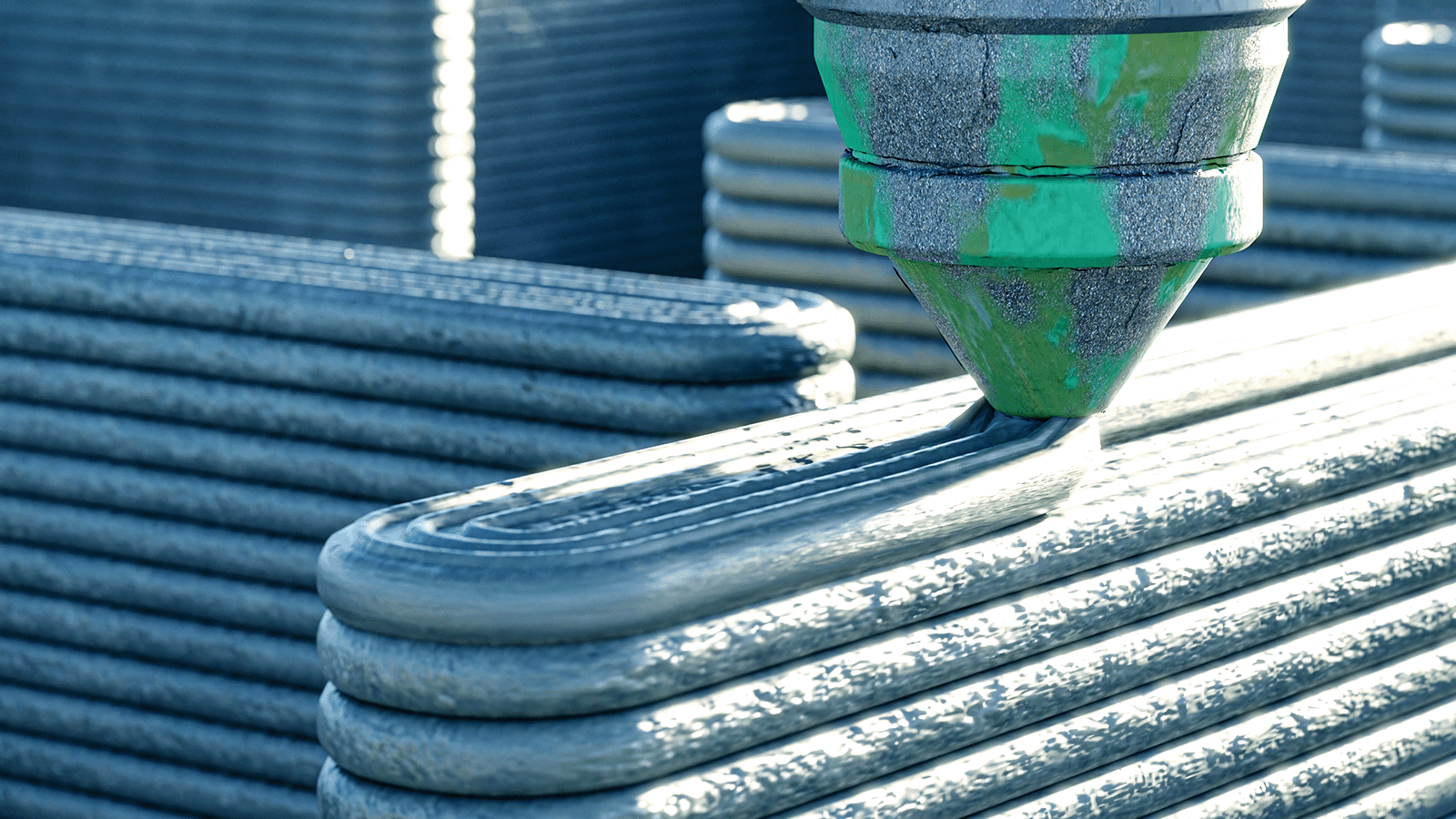

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. It works by adding material layer by layer until the final product is formed. In construction, this technology uses large-scale printers to construct buildings and structures using various materials, including concrete, plastics, and composites.

How Does 3D Printing Work?

- Designing the Model: A digital 3D model is created using computer-aided design (CAD) software.

- Printing the Structure: The 3D printer follows the digital design, extruding material layer by layer.

- Curing and Finishing: Once the layers are built up, the structure is cured and finished as needed.

3. How 3D Printing Works in Construction

Process Overview

- Preparation: Before printing, the site is prepared, and the necessary permits are obtained.

- Material Selection: Various materials can be used in 3D printing, with concrete being the most common in construction.

- Printing: The printer operates continuously, building the structure based on the design.

- Post-Processing: After printing, finishing touches such as insulation, plumbing, and electrical work are completed.

Table: 3D Printing Process in Construction

|

Step |

Description |

|

Design |

Create a digital 3D model using CAD software |

|

Material Selection |

Choose suitable printing materials |

|

Printing |

Operate the 3D printer to build the structure |

|

Post-Processing |

Finish the building with utilities and decor |

4. Benefits of 3D Printing in Real Estate Construction

3D printing offers numerous advantages over traditional construction methods:

- Cost-Effective

- Reduced Labor Costs: Fewer workers are needed on-site, lowering labor expenses.

- Material Savings: Less waste is produced, leading to savings on materials.

- Speed of Construction

- Faster Build Times: 3D printing can significantly reduce the time required to construct a building, often completing structures in days rather than months.

- Design Flexibility

- Custom Designs: 3D printing allows for more intricate designs and customizations that are often difficult or expensive to achieve with traditional methods.

- Sustainability

- Eco-Friendly Materials: Many 3D printing processes use sustainable materials, reducing the carbon footprint of construction.

- Waste Reduction: The additive process minimizes waste, making it more environmentally friendly.

- Improved Safety

- Fewer On-Site Hazards: With fewer workers needed on-site, the risk of accidents and injuries decreases.

5. Applications of 3D Printing in Construction

3D printing can be applied to various types of construction projects:

Residential Buildings

3D printing technology is being used to construct affordable housing units quickly. For example, companies like ICON in the U.S. have developed homes that can be printed in less than 24 hours, providing quick solutions to housing shortages.

Commercial Properties

3D printing is also being used for commercial buildings, such as offices and retail spaces. The technology allows for innovative architectural designs that can attract customers and enhance functionality.

Infrastructure Development

Beyond residential and commercial buildings, 3D printing is making its mark on infrastructure projects. Bridges, roads, and public facilities are being constructed using 3D-printed elements, offering durability and cost savings.

Table: Applications of 3D Printing in Construction

|

Application |

Description |

Benefits |

|

Residential Buildings |

Quick and affordable housing solutions |

Cost-effective and fast |

|

Commercial Properties |

Innovative designs for offices and stores |

Attracts customers, enhances utility |

|

Infrastructure |

Construction of bridges and public facilities |

Durable, sustainable, and efficient |

Also Read: How to effectively use online platforms and offline networking for real estate purchases?

6. Case Studies of 3D Printing in Real Estate

Case Study 1: ICON and the 3D-Printed Home

Overview: ICON, a Texas-based company, has developed a 3D printer called Vulcan that can build homes in a matter of hours. Their homes are designed to provide affordable housing solutions.

- Cost: Approximately $10,000 per home

- Time: Each home can be printed in less than 24 hours.

Case Study 2: Apis Cor

Overview: Apis Cor is a Russian company that created the first 3D-printed house on-site in just 24 hours. The company focuses on using 3D printing to address housing shortages in various regions.

- Cost: Approximately $150,000 for a 400 sq ft house

- Materials Used: Concrete mixtures tailored for 3D printing.

Table: Case Studies Overview

|

Company |

Project Name |

Cost |

Time |

Material Used |

|

ICON |

Vulcan Home |

$10,000 |

< 24 hours |

Concrete |

|

Apis Cor |

3D-Printed House |

$150,000 |

24 hours |

Concrete mixtures |

7. Challenges and Limitations of 3D Printing in Construction

Despite its benefits, 3D printing in construction faces several challenges:

- Regulatory Hurdles

- Building codes and regulations may not yet accommodate 3D-printed structures, leading to potential legal issues.

- Material Limitations

- The variety of materials available for 3D printing is still limited, which can restrict design options.

- High Initial Costs

- While 3D printing can save money in the long run, the initial investment in printers and technology can be substantial.

- Skilled Labor Requirements

- The technology requires skilled workers familiar with 3D printing processes and machinery.

8. Future Trends of 3D Printing in Real Estate

Increased Adoption

- As technology becomes more accessible, more construction companies will adopt 3D printing, particularly for residential projects.

Integration with Smart Technology

- Future 3D-printed homes may integrate smart technologies for energy efficiency and automation.

Sustainable Practices

- Emphasis on sustainable construction practices will drive further research and development in eco-friendly materials for 3D printing.

Sustainable Practices

- Traditional construction methods may integrate 3D printing to enhance efficiency, such as using 3D-printed components in conventional builds.

Conclusion

3D printing is poised to revolutionize the real estate construction industry by offering innovative solutions to long-standing challenges. With its cost-effectiveness, speed, and design flexibility, this technology can significantly impact how we build homes and infrastructure. While there are challenges to overcome, the future looks promising for 3D printing in real estate. As the industry adapts to this technology, we can expect to see a shift in how properties are designed, constructed, and inhabited.

Also Read: How Remote Working is Shaping Real Estate Investment in India

_1772441702.webp)

Ans 1. 3D printing in construction refers to using additive manufacturing to build structures layer by layer from a digital model.

Ans 2. Benefits include cost savings, faster construction, design flexibility, sustainability, and improved safety.

Ans 3. Yes, 3D printing can be used for various building types, including residential, commercial, and infrastructure projects.

Ans 4. Common materials include concrete, plastics, and composites specifically designed for 3D printing applications.

Ans 5. Challenges include regulatory hurdles, material limitations, high initial costs, and the need for skilled labor.